Potential for Increasing Indian

Exports of RMG and Textile products to the German market – Embassy of India, Berlin, Germany

(2022-2023)

-

CSI performed the study to investigate the situation and areas of improvement regarding Indian

RMG imports in Germany.

-

CSI analysed all aspects and consolidated all as informative as possible to aware the industry

regarding facts and figures to develop its strategy for increasing the RMG export percentage to

the German market.

-

Finally, an action plan is recommended to grow more competitive and increase the RMG exports

from India to Germany.

Circularity Denim

Capacity

Building Pakistan – The Netherlands Ministry of Economic Affairs and Climate Policy

(2022-2023)

-

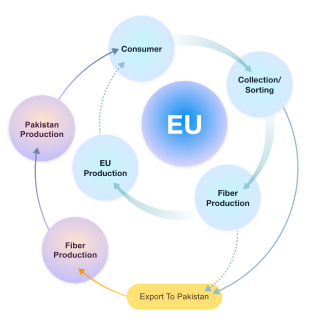

CSI supports building capacities in circularity with a focus on denim recycling by

enabling a pool of factories in the denim supply chain to integrate concepts of

circularity in their production.

-

Created opportunities through trainings and workshops focusing on market and business

orientation that raise awareness and help understand market and customer requirements.

-

We developed a recycled denim cluster by establishing a pool of well-trained

professionals, creating synergies between factories, and facilitating cooperation.

-

The project helped to understand the barriers and challenges regarding technical issues

and other aspects, like importing the PCW from Europe and using PCW in the denim

production processes.

Workshops – German

Due Diligence Act (2022-2023)

-

CSI conducted several workshops on German Due Diligence Act for brands and trade organizations,

i.e., Woolworth, Amfori and Bangladesh-German Chamber of Commerce and Industry (BGCCI).

-

CSI gave an overview of the key areas of Due Diligence and its Impact on the sourcing practices

and the supply chain.

Study on Recycled PET

Understanding the Landscape of Recycled Polyester in Pakistan – WWF Pakistan (2021-2022)

-

CSI assessed the landscape of recycled polyester (PET) in Pakistan and the current global market

requirements for recycled polyester.

-

CSI's study portrayed the situation of Pakistan's recycled polyester industry and the polyester

manufacturers. The study demonstrated the key findings and laid out recommended actions of the

potential scopes for further industry improvement.

-

Two dismission sessions shared the study's outcome with the industry stakeholders.

Sustainable

‘Pakistan’ – Improving Social and Labour Standards in the Textile and Garment Sector of

Pakistan, GIZ PK (2019 – 2021)

-

‘Sustainable Pakistan’ aims to improve labour and environmental standards in Pakistan’s

textile, apparel, leather, footwear, and sporting goods industries.

-

CSI enables suppliers to align their compliance performance with the requirements of

essential consumer markets (e.g., EU, US), thereby attracting new business to Pakistan.

With a transparent management system, manufacturing firms learn to manage compliance and

strengthen their competitiveness.

-

Sustainable Pakistan is determined to improve the country’s reputation as a

manufacturing hub. Suppliers are being developed to participate in international trade

shows and increase their exposure to the global market.

-

The project is dedicated to developing innovative and sustainable solutions for the

fashion industry. Both buyers and suppliers will realize that advanced, transparent, and

cost-efficient manufacturing can align with compliance requirements.

-

Sustainable Pakistan has been recognized for its innovative design in the German Design

Award 2021

Developing and

implementing social, environmental, and chemical compliance standards at four footwear manufacturers

in Indonesia – Josef Seibel (2018-2020)

-

CSI trained and enabled to independently implement relevant environmental and social standards

based on cads at all participating factories.

-

CSI introduced sustainable standards and innovative materials in the shoe manufacturing

processes.

-

CSI trained the factories using innovative materials, including testing methods and developing

product samples using innovative materials and created a sustainable material library.

-

Through cooperation with the local leather polytechnic institute ATK, the knowledge built

through the project was transferred to the wider market by developing teaching materials for the

industry.

Social and Environmental Compliance Handbook, World Bank (2017-2019)

- CSI was assigned by the World Bank within the Export Competitiveness for Jobs (EC4J) project to produce two Compliance Handbooks: one for the leather and footwear industry, another for the plastics and light engineering industries (engineering works, electrical, electronics, batteries, bicycle, motorcycle)

- The handbooks list general and industry-specific non-compliances in labour standards, Occupational Safety and Health (OSH) and environmental protection. They provide recommendations on how to close the compliance gaps and highlight the benefits that can be induced at the worker, company, and societal level.

- Detailed value chain analyses mapping the structures, processes and dynamics of the leather, footwear, plastics and light engineering industries give us a profound understanding of the key stakeholders and the challenges in the corresponding sectors.

Feasibility study for a technology centre for the leather goods and footwear sector in Bangladesh, World Bank (2018)

- A feasibility assessment and develop a viable business model for establishing a design and technology centre for the leather goods and footwear industry.

- The centre's diverse range of services and technology is expected to improve critical criteria, such as productivity, design, product quality, and compliance.

- The study focused on meeting immediate needs to strengthen its position in the global market, considering the future requirements for sustained competitiveness.

- The study's key findings informed the Government of Bangladesh of the potential of such a centre to secure a competitive and sustainable industry.

Improvement of compliance with social, environmental, and chemical standards at one shoe manufacturer and two partner tanneries in Indonesia – ara Shoes (2016-2018)

- The project focused on insights and developing content for the “Quality Association for Sustainable Footwear and Leather Goods” in cooperation with the Federal Association of the German Footwear and Leather Goods Industry (HDSL).

- CSI supported the project partners by adhering to social and environmental standards and optimising relevant management processes.

- Experience and knowledge were exchanged with a local association of the footwear and leather goods industry & educational institution to achieve a broader effect and reach a wider audience.

Qualification programme for BÄR GmbH in India (2015-2016) – BÄR GmbH

- The project emphasised improving the social and environmental standards, productivity, and quality levels at Bär India and selected partner tanneries through a qualification process.

- The initiative cooperated with the Footwear Design & Development Institute in Chennai, India's Ministry of Commerce, and Industry.

- In cooperation with a Chennai-based education partner, CSI created possibilities for practice-oriented training for project partners.

- CSI supported the project partners in implementing a modern management system for adhering to social and environmental standards and production and quality standards.

Pilot projects – Development and implementation in sustainable production.

-

Innovation is key to finding more sustainable solutions. Therefore, we are actively working with partners from research, design, industry, manufacturing, and buyers to develop and implement pilot projects that innovate materials, processes, and management approaches.

-

Cotton/Pineapple yarn blended T-shirt – In cooperation with one German client and local partners, CSI developed methods to upscale pineapple fibre into industrial yarn and fabric production for the fashion and textile industry.

-

Natural indigo-dyed denim – International teams from Hong Kong, Dhaka & Berlin created unique denim to re-activate the forgotten industry.

-

CSI offer the world sustainable, high-quality denim using traditional craftsmanship, the best materials and efficient production processes.Innovation is key to finding more sustainable solutions. Therefore, we are actively working with partners from research, design, industry, manufacturing, and buyers to develop and implement pilot projects that innovate materials, processes, and management approaches.